Brookfield

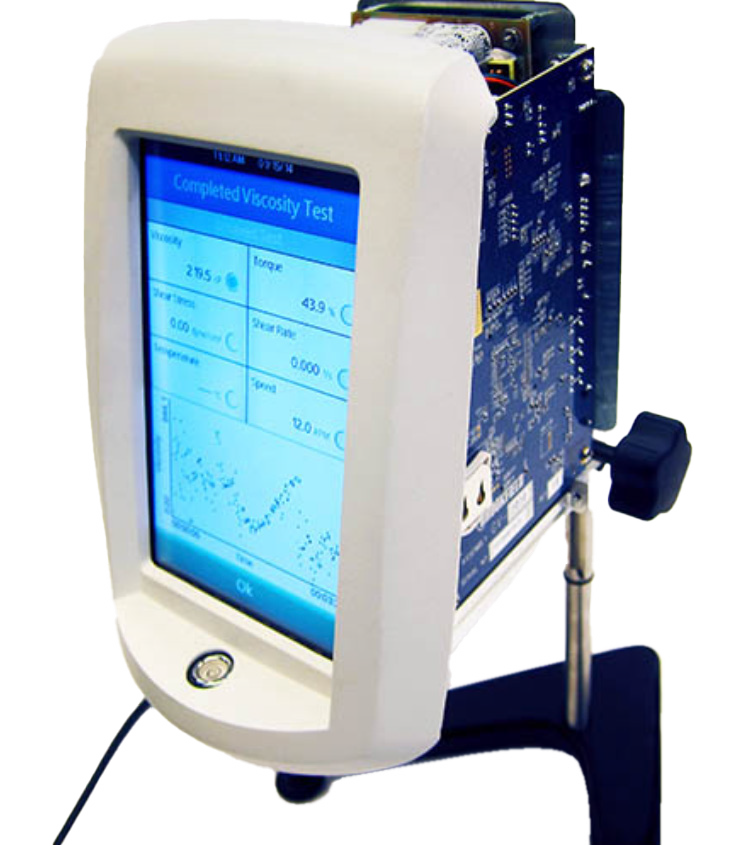

Impact ES–Rhode Island partnered with Brookfield to modernize their viscometers by integrating touch screen technology with the established world-standard features of Brookfield’s DV-II Viscometers and DV-III Rheometers. The goal was to replace the push-button and character-based LCD interface with a modern color graphics LCD while ensuring seamless operation and maintaining precise motor and torque analysis.

Brookfield, renowned for their excellence in mechanical design, needed a user-friendly interface upgrade that leveraged modern technology while maintaining their industry-leading performance. The key challenges included:

Implementing a high-performance color LCD with touch functionality.

Meeting stringent electronic and firmware requirements, including AD sample rates in the 10-nanosecond range.

Ensuring 100% motor speed accuracy.

Designing two models with different screen sizes and features while maintaining a unified software base.

Delivering a market-ready product within a one-year deadline for presentation at Pittcon Conference 2013.

To meet the project timeline, Impact ES–Rhode Island developed the electronics, firmware, and user interface in parallel. The design process involved:

Selecting a Freescale IMX processor to handle high-speed data processing and graphical rendering.

Leveraging Impact ES–Rhode Island’s proprietary royalty-free finite state machine kernel, refined over 20 years, to manage over 200 software states efficiently. This system provided built-in support for alarms, user interface screens, event logging, and protected memory access.

Implementing SimGUI, a proprietary tool that enabled UI development and testing on a PC running Visual Studio. This approach allowed early UI iterations, enabling Brookfield’s marketing team to refine the interface before hardware production.

Writing all embedded software in C, ensuring seamless portability to the final hardware.

Impact ES–Rhode Island successfully delivered a state-of-the-art viscometer interface, enhancing ease of use and expanding functionality. Key improvements included:

Real-time on-screen graphing with options for saving, printing, or PC viewing.

Integrated math models for rapid data analysis.

Multiple data transfer methods, including flash drives and direct PC connection.

On-time product release and highly positive reception at Pittcon Conference 2013.

Parallel development of hardware, firmware, and UI can accelerate project timelines without compromising quality.

A royalty-free custom kernel provides flexibility and efficiency in embedded systems.

SimGUI allows early UI validation, reducing costly rework in hardware-dependent stages.

Strategic code reuse enables the development of multiple product models while maintaining a unified software foundation.

Modernizing user interfaces can enhance product usability and market competitiveness while preserving core functionality.