Medical Device Manufacturer

Impact ES–Rhode Island developed a LabVIEW-based testing application that enables users to control and modify test procedures by simply editing a text file. The application was designed for a medical device that analyzes a patient’s breath to detect lung infections, requiring precise control over numerous pumps and valves.

The complexity of the medical device’s testing requirements posed significant challenges:

• The device’s multiple pumps and valves had various operational states that required precise coordination.

• Testing procedures needed to be highly customizable to support rigorous

validation processes.

• Any modifications to test procedures had to be easily implemented without requiring software recompilation.

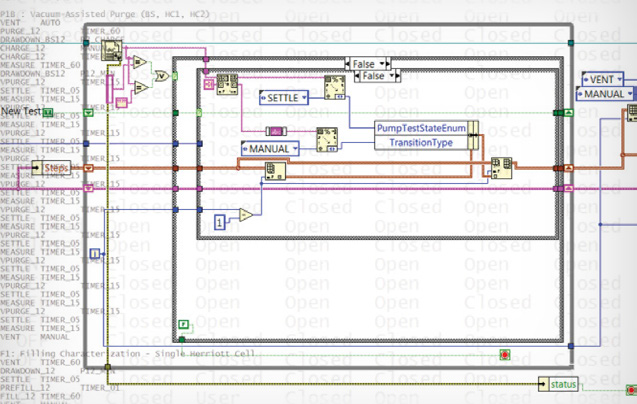

Impact ES–Rhode Island designed a LabVIEW application that utilizes a dynamic state machine, enabling:

• Users to define and modify test procedures by simply editing a whitespace-delimited text file.

• The creation of new system states and test sequences without requiring changes to the underlying code.

• Seamless test execution by reloading the text files, reducing downtime and improving efficiency.

The LabVIEW-based application provided a user-friendly, flexible solution that streamlined the testing process for the client’s medical device. The ability to modify tests without recompilation significantly enhanced adaptability, making it easier to conduct thorough and customized testing procedures.

Dynamic state machine architectures enable highly flexible and adaptable testing environments.

• Using text-based configurations reduces development time and increases usability for non‐programmers.

• LabVIEW provides a powerful platform for controlling and automating complex testing procedures.

• Customizable test procedures allow for rapid adjustments in response to new validation requirements.

• Streamlining test execution improves efficiency and reduces downtime in medical device development.