Aerospace industry client requiring precise alignment of components during aircraft modification.

Develop a tool to measure the relative azimuth of components located in two different locations on an aircraft, with alignment accuracy within 0.5 degrees.

Measuring relative azimuth (or yaw) between components in an aircraft is difficult when line-of-sight is not available. Traditional tools like transits or laser trackers cannot be used in such cases. Magnetic compasses are also impractical due to varying magnetic effects caused by different aircraft components, which introduce errors depending on the location.

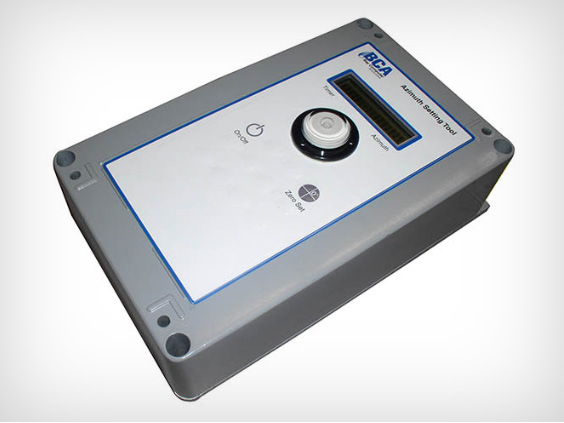

Impact ES–Rhode Island developed the Azimuth Setting Tool (AST), which uses a single-axis fiber optic gyro (FOG) to sense the relative azimuth between two objects or features. The AST allows a technician to measure the azimuth of an existing feature, carry that measurement to another location, and align an object to the original azimuth reading within 0.5 degrees.

The AST provided a simple, effective way to make critical component alignments without requiring line-of-sight or magnetic instruments. It is designed for use by production technicians or line mechanics in the field, where typical production tools may not be practical or available.

Uses a fiber optic gyro to overcome limitations of line-of-sight and magnetic interference

Enables precise alignment within 0.5 degrees

Simple to operate with no need for user interpretation

Field-ready for use during aircraft modification and installation tasks