Scanning Electron Microscope Manufacturer

Impact ES–Rhode Island developed electronics and FPGA firmware for a subsystem responsible for steering and focusing the beam of a Scanning Electron Microscope (SEM) used to detect defects in silicon wafers. The system required precise voltage control, synchronization, and minimal electrical noise to ensure high-quality imaging.

The customer’s SEM design included multiple stages, each operating at different electrical potentials, sometimes up to kilovolts apart. Each stage required a driver capable of producing precise voltage signals while maintaining near-perfect synchronization with other stage drivers.

The key challenges included:

High-speed synchronization across multiple driver boards.

Electrical isolation due to varying voltage potentials.

Extremely low electrical noise to prevent image degradation.

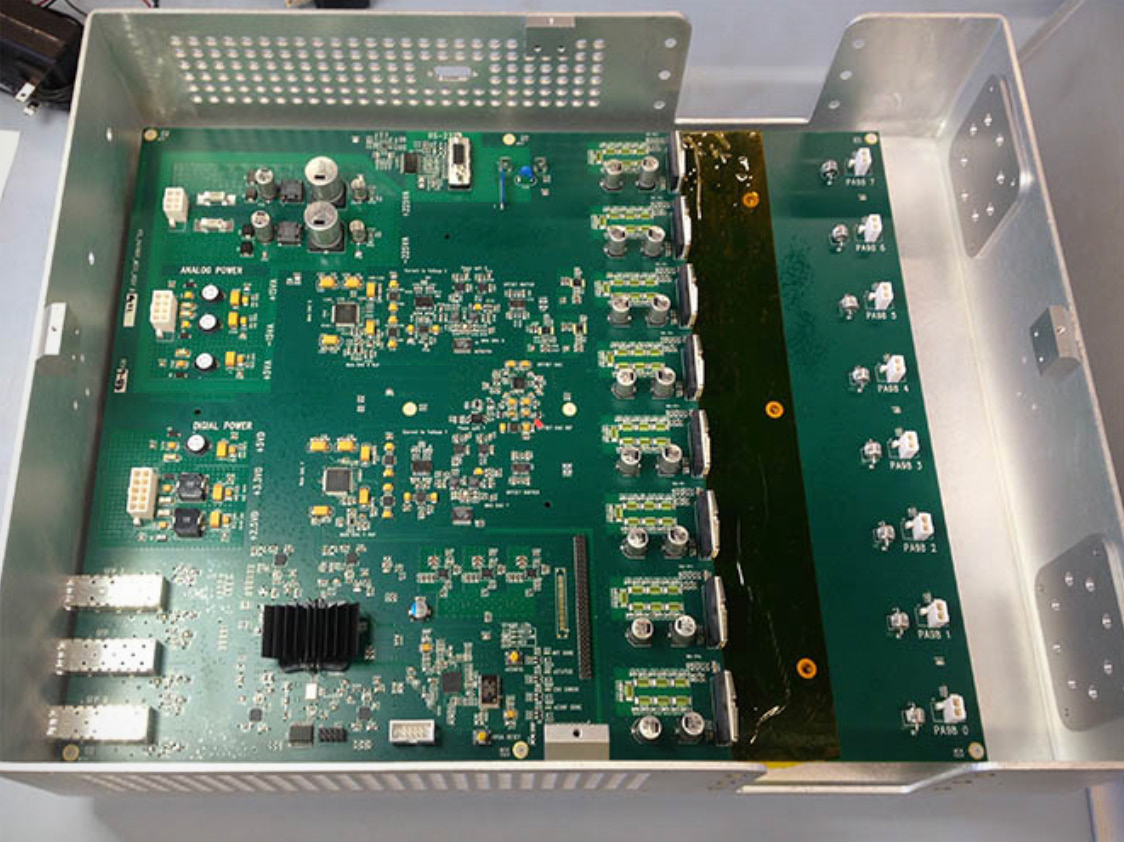

Impact ES–Rhode Island collaborated with the customer to define exact requirements and develop a system architecture that met all specifications. The final design consisted of:

A driver board for each stage to generate the required voltage signals.

A controller board to manage communication and synchronization across all driver boards.

Fiber optic links between the controller and driver boards, ensuring high-speed data transmission while maintaining electrical isolation.

Implementation of an Altera Arria II GX FPGA, which handled all processing and communication.

Custom FPGA firmware, including:

High-speed transceiver interfaces for fiber optic communication.

A custom board-to-board communication protocol.

A debug interface for testing and manufacturing validation.

Special attention to parts selection and layout to minimize electrical noise, ensuring optimal image quality.

The FPGA firmware achieved synchronization within tens of nanoseconds, ensuring seamless operation of the SEM stages.

Impact ES–Rhode Island successfully designed, built, tested, and delivered a fully functional system that met or exceeded all customer requirements. The resulting system provided superior synchronization, exceptional noise reduction, and high-speed operation, significantly improving the performance of the SEM.

High-speed synchronization and precision voltage control are critical in advanced SEM applications.

Fiber optic links provide effective electrical isolation while enabling fast data communication.

FPGA-based control systems allow for custom, high-performance solutions tailored to specific application needs.

Attention to electrical noise mitigation in design and component selection ensures high-quality imaging results.

A well-structured collaboration between engineering teams leads to highly optimized, successful product development.