International Leader in Medical and Safety Technology

Impact ES–Rhode Island was engaged by an international leader in medical and safety technology to design an FPGA controller capable of interfacing with multiple systems. The FPGA needed to communicate with two distinct ADCs (analog-to-digital converters) while also managing UART, I2C, and SPI communication protocols. Additionally, it needed to package and send data to a microcontroller while allowing field programmability for usability enhancements.

The FPGA needed to handle a large volume of data from various input sources efficiently. It had to:

Seamlessly interface with two ADCs.

Send and receive messages via UART, I2C, and SPI.

Enable the microcontroller to configure ADC registers and send FPGA commands.

Support field programmability through one of the communication methods.

Operate within strict space constraints while maintaining full functional

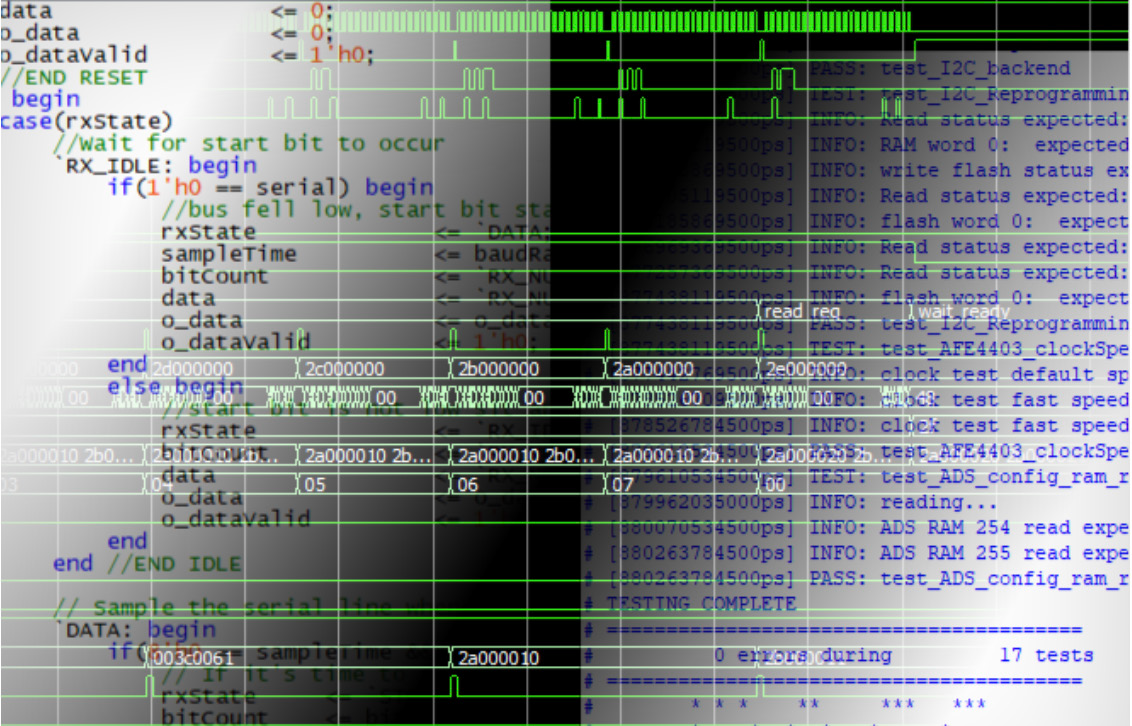

To efficiently manage data flow, Impact ES–Rhode Island modularized the FPGA design, creating distinct modules to interface with each external component. A structured data bus was implemented within the FPGA to facilitate inter-module communication, with master-access modules managing read/write operations across registers. Custom bus arbitration logic was developed to prevent data collisions.

To achieve field re-programmability, Impact ES–Rhode Island implemented a two-tier system:

To achieve field re-programmability, Impact ES–Rhode Island implemented a two-tier system:

The FPGA bitstream was sent in small chunks to a single-port RAM via I2C.

Once the RAM was filled, it was transferred to the appropriate flash memory location.

The system could read back flash memory to verify correct programming.

A dedicated I2C command enabled system resets under a new firmware image.

A major obstacle was overcoming space constraints, as the compiled design initially exceeded FPGA capacity by 30%. Impact ES–Rhode Island optimized the code, reducing logic gate usage by 40% without sacrificing features. To ensure robust performance, an automated test bench was developed using Impact ES–Rhode Island’s in-house framework. This test suite verified:

Accurate output stream generation from known inputs.

Timing adherence for data transfer.

Successful external updates to internal control registers.

Consistent ADC configuration and data reading.

Proper functionality of internal diagnostic tools.

Impact ES–Rhode Island delivered an optimized FPGA controller design with a full-featured test suite, ensuring reliable operation. The final solution met all functional and space requirements while allowing rapid regression testing for future modifications.

Modular FPGA architecture enables efficient data handling and scalability.

A structured bus system with arbitration logic prevents data collisions and ensures seamless communication.

Field re-programmability enhances usability and extends device longevity.

Space optimization techniques can significantly reduce FPGA logic usage while maintaining full functionality.

Automated testing frameworks provide rapid verification and regression testing for future iterations.