By Colin Campbell, Senior Process Engineer, Impact ES–Vancouver

Many of us at Impact ES–Vancouver remember when creating small fixtures to support production processes cost hundreds of dollars and came with lead times that rarely aligned with the fast pace of our environment. Fortunately, the introduction of 3D printing has eliminated both of these issues.

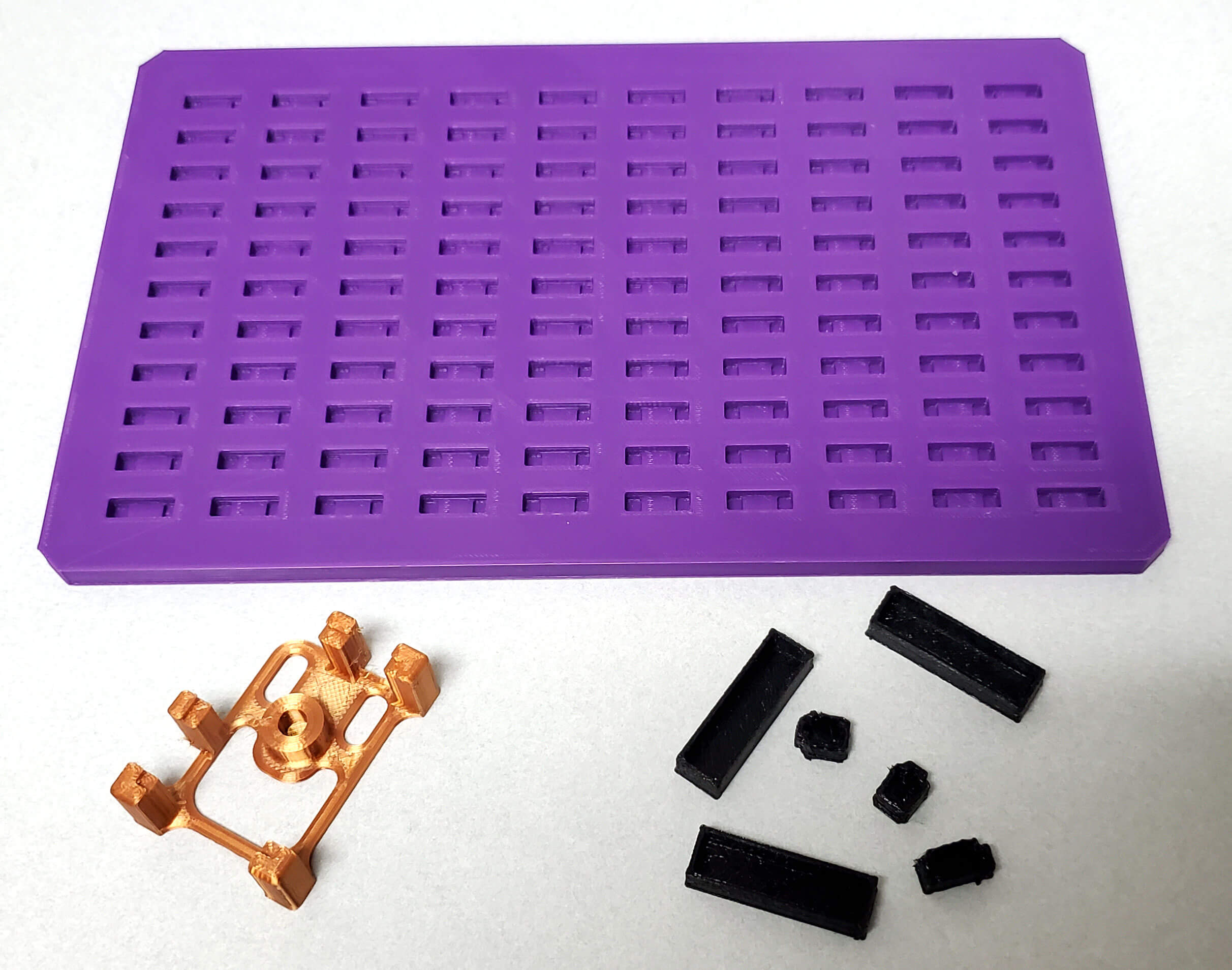

Example of a Matrix Tray, Soldering Fixture, and Conformal Coating Masking Boots used by Impact ES–Vancouver.

Example of a Matrix Tray, Soldering Fixture, and Conformal Coating Masking Boots used by Impact ES–Vancouver.

Today, we can produce small fixtures at a fraction—often just 1/100th—of the original cost, with lead times reduced to just a few hours. As many know, nothing is ever perfect on the first attempt, and revisions at a traditional machine shop can be expensive. With 3D printing, iteration is fast and affordable.

This shift has unlocked significant cost savings and flexibility. We’re now able to experiment with fixture designs we would have previously dismissed due to the high cost of prototyping.

Examples of 3D-printed tools we use include:

Soldering Fixtures: Used to hold boards and components in place, these fixtures provide our operators with better accuracy and ease when hand-soldering.

Conformal Coating Masking Boots: Reusable, flexible covers that protect components during the conformal coating process, significantly reducing masking time.

Matrix Trays: Custom trays for our pick-and-place machines, designed to accommodate parts not delivered in standard packaging—ensuring machine placement remains possible.

And the list goes on. As you can see, integrating 3D printing into our workflow has proven invaluable—likely paying for itself many times over.

By Kevin McCall, Chief Operating Officer, Impact ES–Clearwater

We’re excited to announce that Impact ES–Clearwater is expanding—and this milestone marks more than just additional square footage. It represents the official launch of Production 2.0.

This newly operational space enhances our electromechanical assembly capabilities and introduces a flexible manufacturing area that can be reconfigured based on evolving customer needs. Whether it’s scaling production, accelerating timelines, or adapting to custom build requirements, Clearwater is now equipped to deliver even greater responsiveness and support.

And this is just the beginning. As we grow, so do our capabilities—to serve you with more precision, efficiency, and scale.

More space. More flexibility. More possibilities.

Stay tuned—there’s more on the horizon.

As part of our newsletter, we want to introduce you to our team, share our Impact culture, values, and how we occasionally have fun at work.

The Clearwater team is pleased to welcome three new teammates this month. We’re glad to have them on board and look forward to the impact they will make!

• Mary King – Assembler/Solderer

• Renee Spears– Assembler/Solderer

• Connie Duggan – Assembler/Cables

This summer Impact ES–Grants Pass turned up the heat with a hot dog eating contest and a full cookout for the entire team. Maegon Brazille and John Stone grilled and served over 150 hot dogs! The competition featured three brave contestants: Daniel Kuester, Truman Shanor, and David Haynes. After Truman placed third in the first round, David and Daniel went to sudden death—tied at five dogs in three minutes. In the final bite-for-bite race, Daniel edged out David by a fraction of a second to claim victory. Thanks to everyone who joined in the fun!

We’re proud to share two exciting updates from our Rhode Island facility! Congratulations to Nick Amore, who has been promoted to Senior Electrical Engineer! Since joining Impact ES in 2020, Nick has consistently delivered high-quality engineering solutions across a wide range of industries—including medical, commercial, industrial, and defense.

Please join us in welcoming Arten Esa to the Electrical Engineering team. Arten brings a fresh perspective and solid engineering experience to our growing Rhode Island team. We’re excited to have him on board and look forward to the contributions he’ll bring to our projects.

Join us in giving both Nick and Arten a warm round of applause!

As Impact ES–Vancouver wraps up the first half of 2025, it’s clear—this team is operating at peak performance, meeting critical production targets, delivering on tight deadlines, and upholding the high standards of quality that customers have come to expect. It’s a track record that not only reflects operational excellence but reinforces Vancouver’s reputation as a trusted partner in contract manufacturing.

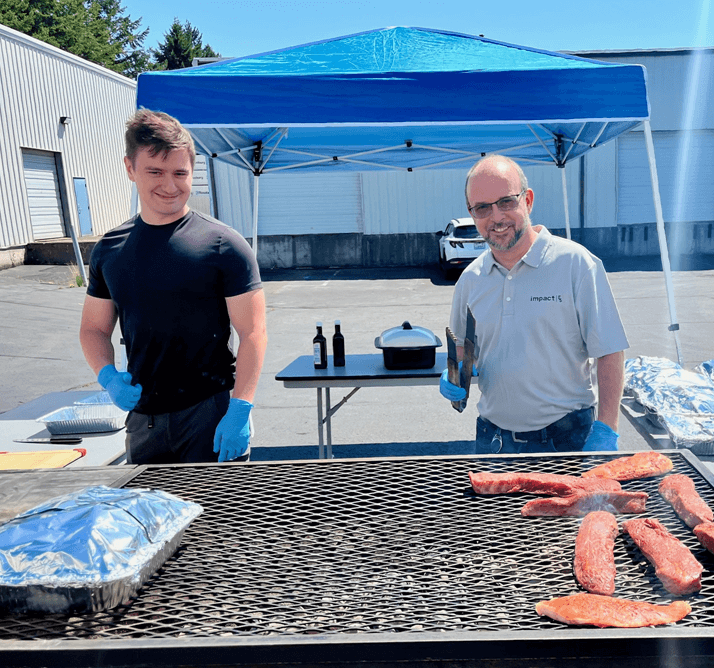

To recognize all the hard work and dedication, the team marked the occasion with one of their favorite traditions: Steak Day. But this wasn’t just about great food—it was a moment to recognize the dedication, teamwork, and pride that fuel this high-performing team.

As the team looks ahead to the rest of 2025, one thing is clear: the momentum is strong, the culture is even stronger, and this crew is more than ready for what’s next.

Please welcome Ryan Dougan as the new Controller of Impact ES–Ventura, who brings over 15 years of experience as a Controller in the Southern California region. A Ventura County native, Ryan is excited to bring his expertise back home and contribute to the community where he was born and raised.

And welcome Felipe Rabelo as the new VP and General Manager of Impact ES–Ventura. Felipe brings over 20 years of global operations experience in electronics manufacturing, leading successful launches in China, Mexico, Brazil, and the U.S. Most recently, Felipe oversaw operations at three sites across Mexico and the U.S. Felipe is fluent in Portuguese, Spanish, and English.

Please join us in giving them a warm welcome to the Impact ES team!

We hope you found this newsletter helpful. Please share it with others and make sure to follow us on LinkedIn for more updates, case studies, and news.