By Dave Girard, Director of Electrical Engineering, Impact ES–Rhode Island

At Impact Electronic Solutions, we know that testing isn’t just about checking a box. It’s about safeguarding performance, protecting reputations, and ensuring that every product works exactly as intended in the most demanding real-world environments.

From aerospace and defense to medical and industrial markets, our customers trust Impact ES to deliver end-to-end testing solutions that uncover issues early, streamline production, and provide the confidence to move forward—whether it’s a single prototype or a high-volume production run.

We’ve captured the full range of our capabilities in a new Testing Capabilities Datasheet, highlighting everything from flying probe and environmental validation to custom test fixtures and full system testers.

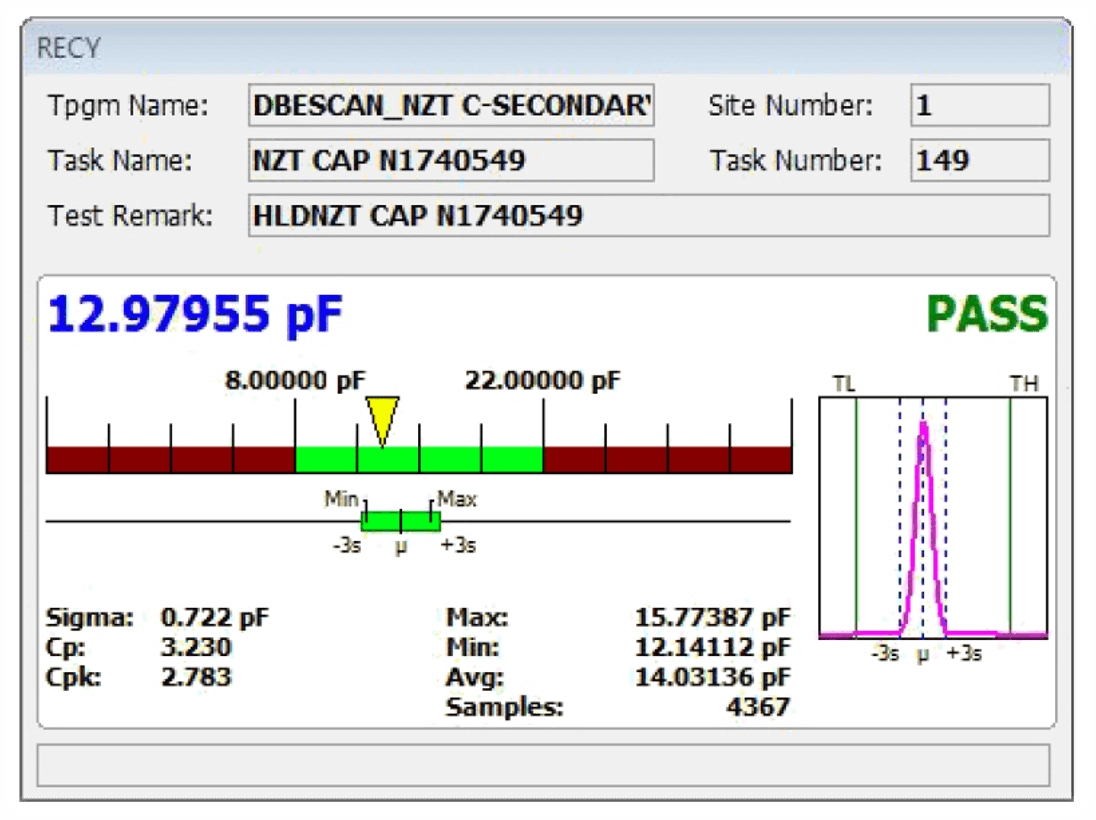

At Impact Electronic Solutions, nearly every board we build begins its testing journey with flying probe. This versatile, fixture-less method allows us to quickly check for shorts, opens, component values, polarity, and unsoldered pins—without the delays or costs of custom fixtures. By making flying probe our testing starting point, we catch potential build issues early in the process, long before boards advance to more complex functional or system-level testing. The result is faster validation, less rework, and greater confidence for our customers that every design is moving forward on a solid foundation.

.jpg)

Impact ES is excited to join the MedTech community in Boston for hands-on workshops, curated networking, and an expo floor filled with cutting-edge technologies. We’ll be showcasing how our end-to-end solutions—from precision manufacturing to advanced test systems—help medical device innovators bring ideas to life, faster and with uncompromising quality.

If you’ll be at MEDevice Boston, let’s connect! We’d love to talk about how we can support your next project. Come visit us at booth #930.

We hope you found this newsletter helpful. Please share it with others and make sure to follow us on LinkedIn for more updates, case studies, and news.