Client

Confidential medical equipment manufacturer

Project Scope

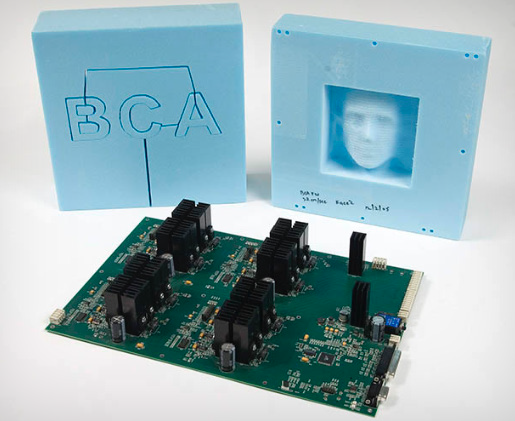

Impact ES–Rhode Island developed electronics, firmware, and software for a machine used to manufacture custom molds for radiation therapy filter production.

Challenge

A manufacturer of medical equipment used in creating custom molds for radiation therapy filters needed upgrades to the electronics, embedded firmware, and PC software across two of their product lines. The goal was to modernize the system while consolidating components for better performance and reduced complexity.

Solution

Impact ES–Rhode Island designed new, simplified electronics housed on a single board to control both product lines. The team developed firmware to manage the electronics and enable communication with the PC software, which was also upgraded.

The newly designed circuit board replaced both the third-party board previously located in the PC and the separate motor-control electronics. The new board was embedded directly in the device, with commands sent from the PC via a serial link.

Key Takeaways

The legacy PC software was outdated both visually and functionally. Impact ES–Rhode Island modernized the graphical user interface and added key features, including:

Upgrading to a 32-bit application compatible with next-generation motor control hardware

Creating a graphical display of the mold shape, allowing users to trace a template with the mouse

Adding configuration options for cutter parameters

Enabling direct entry of patient information into the software

This system was developed for a Class II medical device.

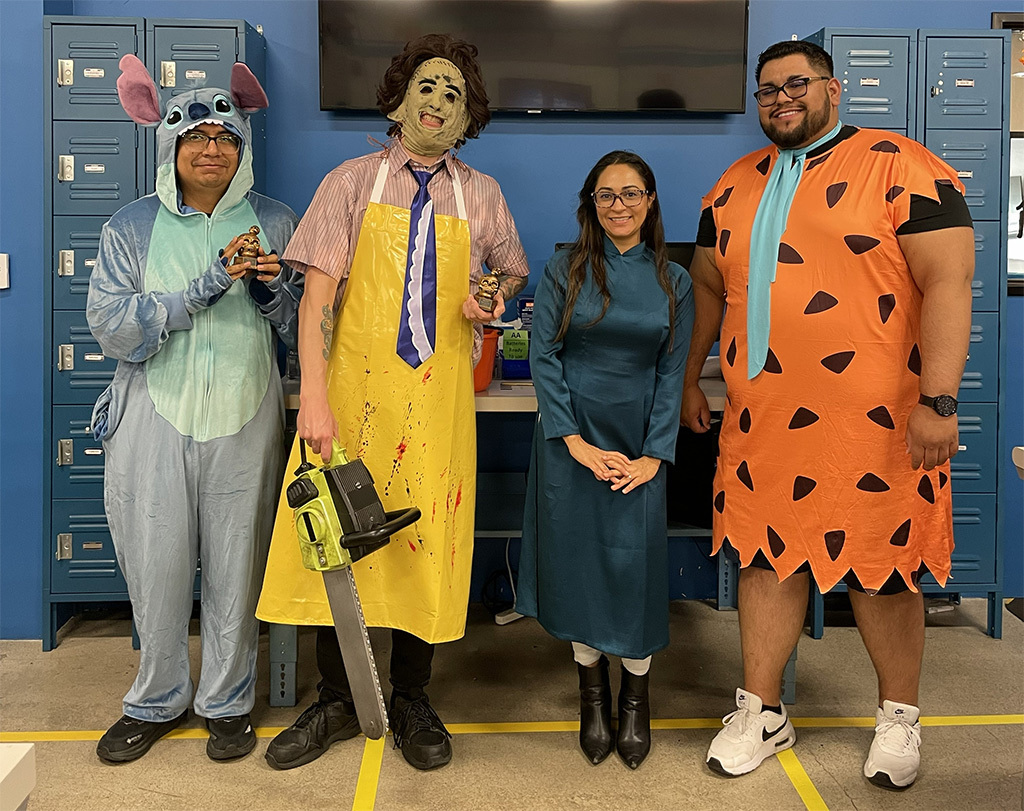

Each month, we take a moment to spotlight the people who make Impact thrive—sharing a glimpse into our culture, values, and the moments that make work fun. This month was no exception as our teams got into the Halloween spirit with creativity, costumes, and plenty of treats.

The team got into the Halloween spirit with a festive hot dog potluck and costume part. From creative costumes to hot dogs piled high with all sorts of toppings, the team celebrated together in true Impact style!

First, we hit our target sales goal—a milestone worth celebrating. To mark the achievement, everyone enjoyed a delicious catered lunch from local favorite La Bottega Deli.

Second, the Easter Bunny made an early appearance with a fun team-building challenge: a friendly competition to build the tallest tower using only plastic Easter eggs. Creativity, laughter, and just the right amount of competitive spirit filled the room as teams worked together to engineer their masterpieces.

Impact ES–Grants Pass went full Squid Game for Halloween this year! Employees received player numbers and were “eliminated” throughout the day via intercom raffle—until Ryland Colegrove (Player #163) claimed victory. Kyle Serino won the costume raffle, and staff enjoyed nachos and caramel popcorn served by our Squid Game Guards. With 36 costumes and special visits—from a real snake to baby Liam—it was one of our most spirited Halloweens yet!

.jpg)

.jpg)

This year’s festivities included a classic cake walk, a raffle for gift cards, and a spooky surprise—participants had to reach into a bowl of Orbeez to claim their prize.

As always, it was a fun and festive break that brought everyone together for a little Halloween magic, Impact-style! Thanks everyone who participated.

Our Ventura team didn’t hold back when it came to Halloween spirit! From Fred Flintstone to Darth Vader, costumes filled the office and reminds us that the same creativity and teamwork that drive our projects also make Impact a fun place to work. We love seeing our teams across the country connecting through shared moments like this.

We hope you found this newsletter helpful. Please share it with others and make sure to follow us on LinkedIn for more updates, case studies, and news.